Abstract:

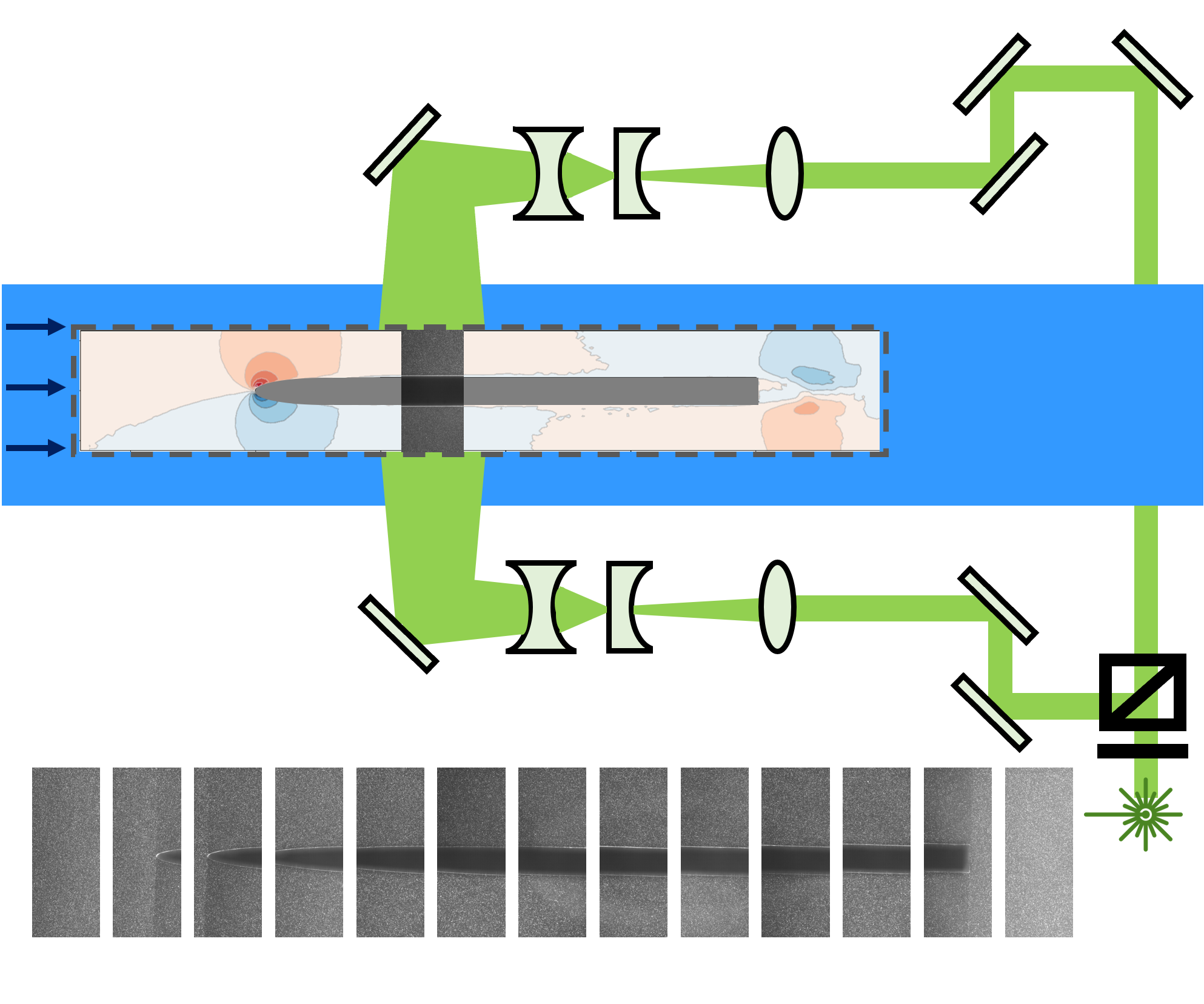

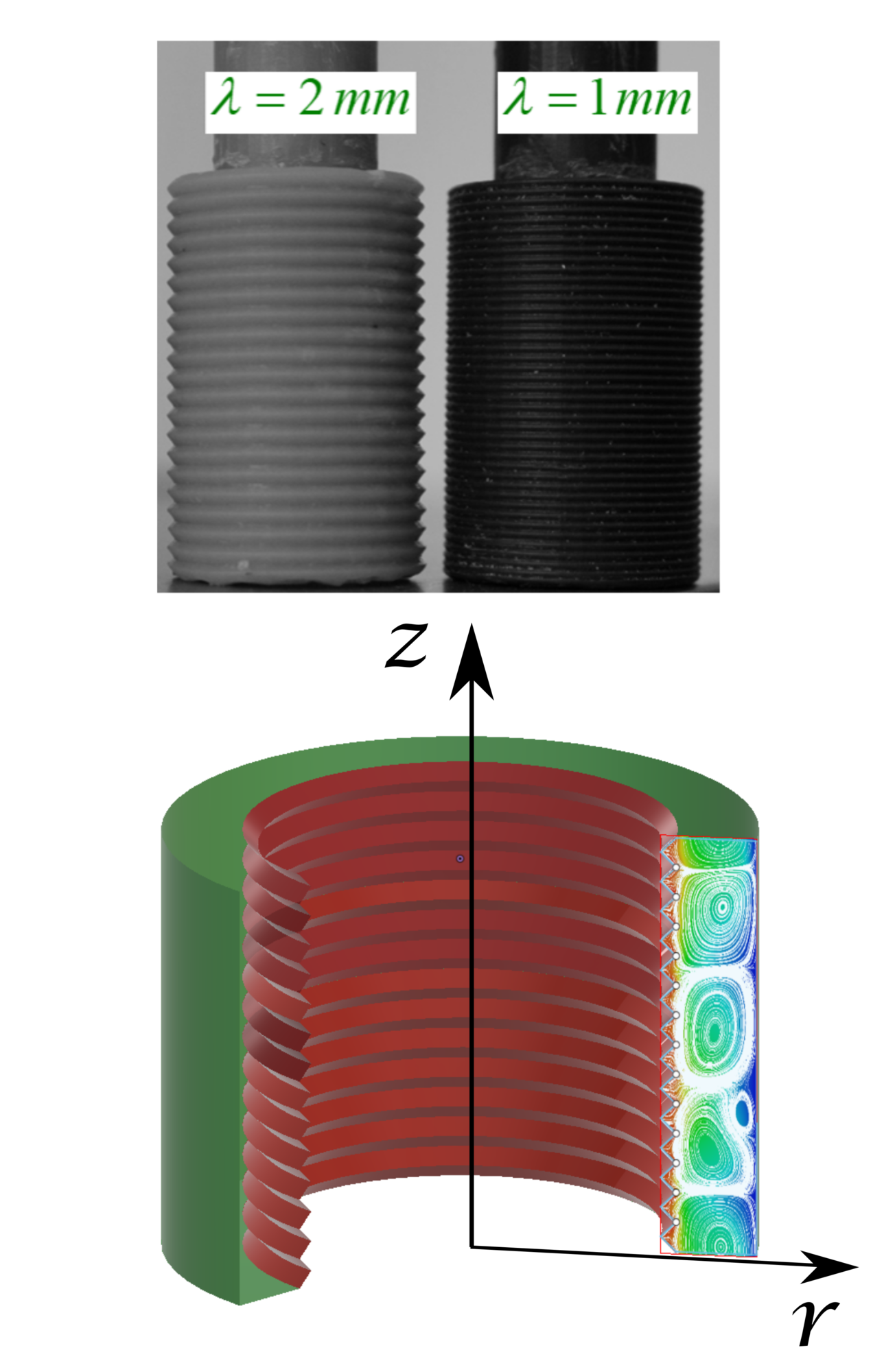

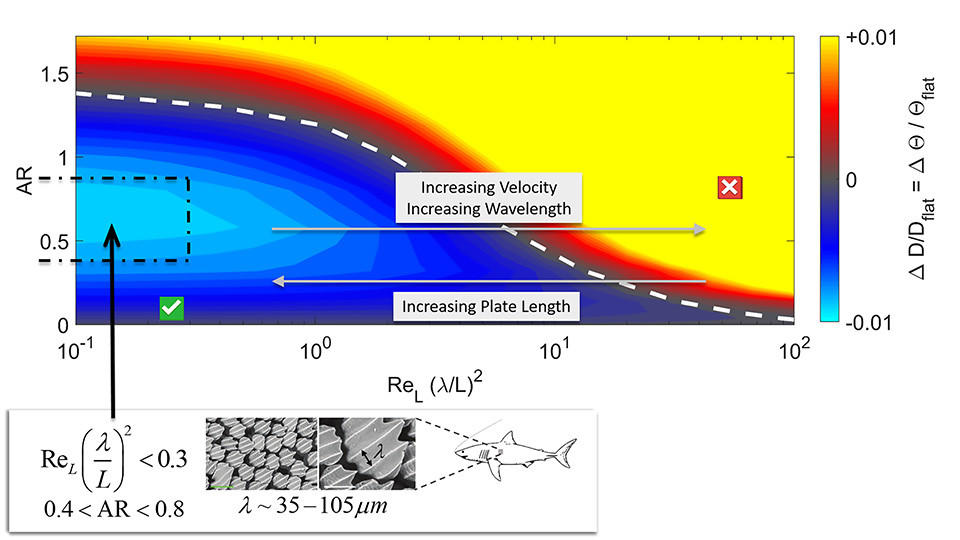

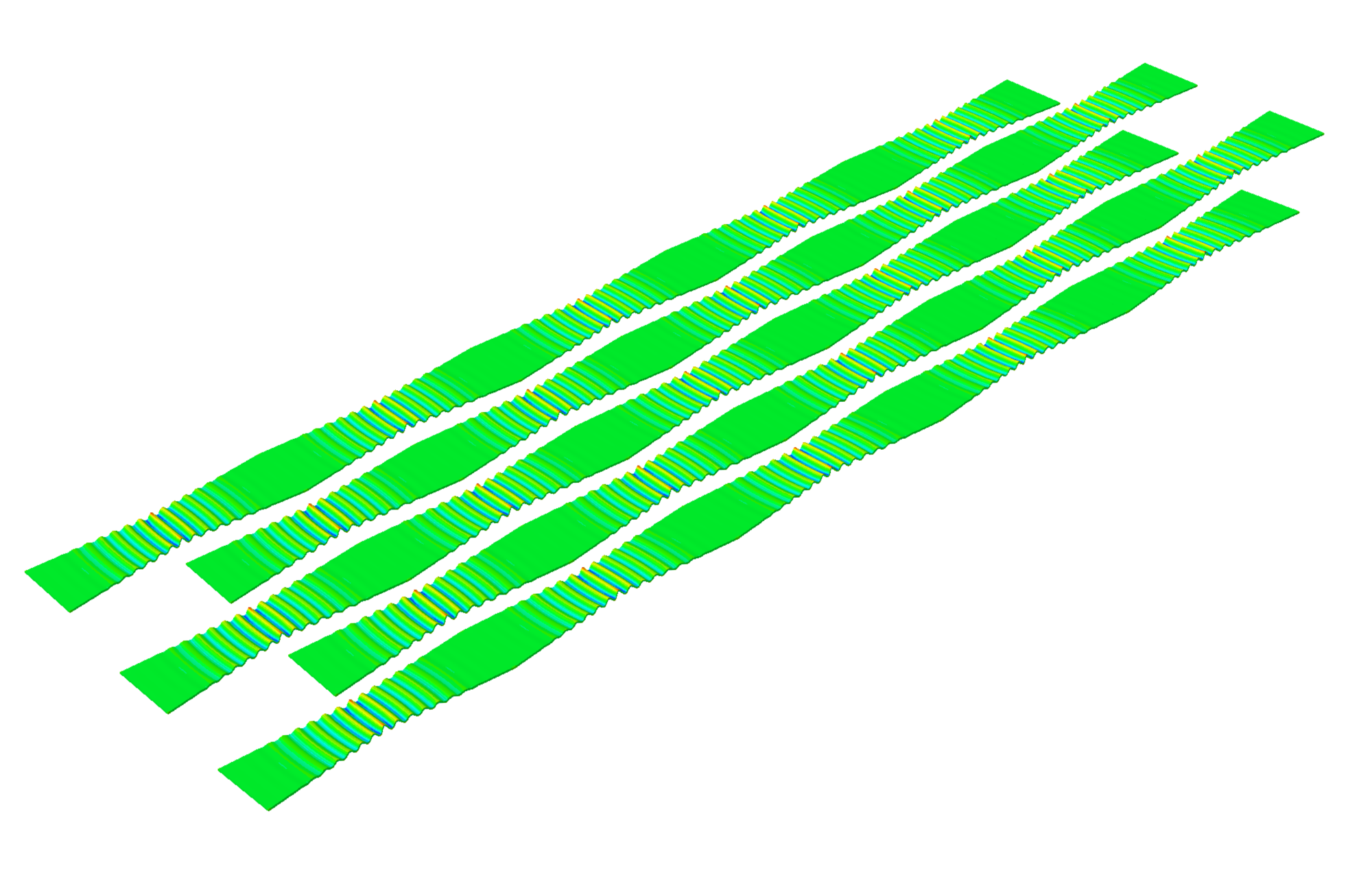

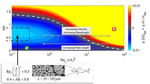

Micro-scale riblets are shown to systematically modify viscous skin friction in laminar flows at high Reynolds numbers. The textured denticles of native sharkskin are widely cited as a natural example of this passive drag reduction mechanism. Since the structure of a viscous boundary layer evolves along the plate, the local frictional drag changes are known empirically to be a function of the length of the plate in the flow direction, as well as the riblet spacing, and the ratio of the height to spacing of the riblets. Here, we aim to establish a canonical theory for high Reynolds number laminar flow over V-groove riblets to explore the self-similarity of the velocity profiles and the evolution of the total frictional drag exerted on plates of different lengths. Scaling analysis, conformal mapping, and numerical calculations are combined to show that the potential drag reduction achieved using riblet surfaces depends on an appropriately rescaled form of the Reynolds number and on the aspect ratio of the riblets (defined in terms of the ratio of the height to spacing of the texture). We show that riblet surfaces require a scaled Reynolds number lower than a maximum threshold to be drag-reducing and that the change in drag is a nonmonotonic function of the aspect ratio of the riblet texture. This physical scaling and the computational results presented here can be used to explain the underlying physical mechanism of this mode of passive drag reduction to rationalize the geometric dimensions of shark denticles, as well as the results of experiments with shark denticle replicas of various sizes, and guide designs for optimizing the textural parameters that result in friction-reducing surfaces.